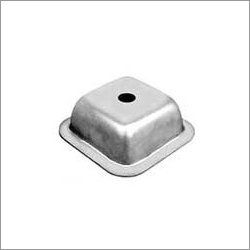

Drop Forged Swivel Coupler

Drop Forged Swivel Coupler Specification

- Components

- Body, T-Bolt, Nut, Washer

- Hole Size

- 48.3 mm (standard for scaffolding tube)

- Other Features

- Corrosion resistant, High tensile strength, Reusable

- Application

- Scaffolding construction, Pipe joining, Industrial frameworks

- Load Capacity

- Up to 6 kN (kilonewton)

- Shape

- Swivel (allows rotation)

- Thickness

- 4 mm to 6 mm (as per requirement)

- Material

- Drop Forged Steel

- Surface Finishing

- Electro Galvanized / Hot Dip Galvanized / Zinc Plated

- Packaging Type

- Gunny bag or carton boxes according to requirement

- Weight

- Approx. 1.10 kg per piece

- Bolt Size

- 1/2" BSW or M12 (standard)

- Color

- Silver/Golden (depends on surface finish)

- Standards

- BS1139/EN74 Compliant

- Coupler Type

- Swivel Coupler / Right Angle Coupler

- Usage

- Connects two scaffold tubes at any angle

- Rotation Angle

- 360 degrees

- Clamping Range

- Compatible with 48.3 mm OD tubes

About Drop Forged Swivel Coupler

Our drop forged swivel couplers are made of high-grade steel material and are designed to be compatible with scaffolding pipes. These couplers are robust, durable and easy to install. We provide them in different sizes and specifications as per customer requirements. Our drop forged swivel couplers are widely used in various construction projects and other industrial applications. They are highly appreciated for their high tensile strength, corrosion resistance and dimensional accuracy.Versatile and Durable Scaffold Coupler

This swivel coupler adapts to diverse framework requirements, allowing right angle or flexible pipe connections in construction and industrial environments. Its drop forged steel body and adjustable thickness ensure enduring strength while its corrosion-resistant finish provides longevity in challenging conditions. It effortlessly connects 48.3 mm OD tubes, supporting dynamic projects with reliability and safety.

Enhanced Safety and Compliance

Engineered to comply with BS1139 and EN74 standards, this coupler delivers assured performance for professional scaffolding setups. It boasts a high load capacity of up to 6 kN and incorporates precision-built components, including a robust T-bolt, nut, and washer, guaranteeing secure joining even under demanding circumstances.

FAQ's of Drop Forged Swivel Coupler:

Q: How does the Drop Forged Swivel Coupler operate to connect scaffold tubes?

A: The coupler uses its 360-degree rotation capability to join two scaffold tubes at any angle, making it suitable for complex scaffold configurations. Its drop forged steel construction and precise fittings ensure a secure and stable connection.Q: What is the process for installing this right angle swivel coupler?

A: Installation involves sliding the coupler over the standard 48.3 mm diameter tubes, aligning them as needed, then tightening the included bolt and nut to achieve a firm hold. The process is simple and quick, requiring only basic scaffolding tools.Q: When is it recommended to use this coupler in construction projects?

A: This coupler is ideal for situations where scaffold tubes need to be joined at non-standard angles or require a flexible, rotating joint. It is commonly used in building scaffolds, pipe frameworks, and structural assemblies in construction or industrial settings.Q: Where can the Drop Forged Swivel Coupler be applied?

A: It finds application in scaffolding construction, industrial frameworks, and pipe joining projects where high tensile strength and reliable safety standards are paramount. The product is suitable for use across various industries worldwide and is supplied/exported from India.Q: What are the benefits of using a drop forged, BS1139/EN74 compliant coupler?

A: Benefits include high load bearing capacity (up to 6 kN), durability against corrosion, compliance with international safety standards, reusability, and ease of installation. Its standardized size ensures compatibility with typical scaffolding tubes.Q: How does the surface finish enhance the coupler's durability?

A: Options such as electro galvanized, hot dip galvanized, or zinc plated surface finishes provide robust protection against rust and weathering, extending the lifespan of the coupler and maintaining its performance in harsh environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Couplers and Fittings Category

Industrial Stair Case Coupler

Surface Finishing : Galvanized / Zinc Plated

Material : Mild Steel (MS)

Other Features : Corrosion resistant; Precision engineered for durability

Application : Joining and securing staircase planks or handrails in industrial scaffolding and construction frameworks

Shape : Rectangular with Precise Form

Components : Staircase Coupler with Bolt and Nut

Industrial Pallet Bowl

Surface Finishing : Galvanized

Material : Mild Steel

Other Features : Corrosion resistant, Heavy Duty Construction

Application : Material Handling, Storage, Warehousing

Shape : Round

Components : Industrial Pallet Bowl

Industrial Drop Forged Swivel Coupler

Surface Finishing : Zinc Plated / Hot Dip Galvanized

Material : Drop Forged Carbon Steel

Other Features : 360 Rotation, Heavy Duty, Corrosion Resistant

Application : Scaffolding, Construction, Tube and Coupler Systems

Shape : Swivel

Components : Swivel Coupler Body, Two Bolts, Nuts, Washers

Industrial Fencing Coupler

Surface Finishing : Hotdip galvanized

Material : Galvanized steel

Other Features : Corrosion resistant

Application : Industrial fencing panel connection

Shape : Rectangular

Components : Coupler body, securing bolts, nuts

Send Inquiry

Send Inquiry