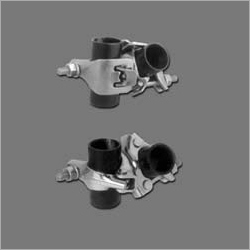

Pressed Double Coupler

Pressed Double Coupler Specification

- Application

- Scaffolding Pipe Fittings, Construction, Building Support

- Components

- Pressed Body with Swivel Bolts and Nuts

- Load Capacity

- Up to 6.25 kN (as per EN 74 Standard)

- Thickness

- 3 mm to 5 mm (customizable)

- Hole Size

- Designed for 48.3 mm diameter scaffolding tube

- Other Features

- Anti-corrosive, Reusable, Conforms to BS1139/EN74 standards

- Shape

- Double Coupler (Right Angle) Clamp

- Material

- Forged or Pressed Steel

- Surface Finishing

- Electro-galvanized / Hot Dip Galvanized

- Clamp Type

- Pressed Steel Right Angle Coupler

- Operation

- Secures Two Scaffold Tubes at 90 degrees

- Color

- Silver / Golden Yellow (zinc plated)

- Durability

- High strength and long service life

- Weight

- Approx. 1.05 kg per piece

- Standards

- EN74, BS1139 Certified

- Bolt Size

- 1/2 inch BSW Threaded Bolts

- Compatibility

- Fits standard 48.3 mm OD scaffold pipes

- Packaging

- 25 pieces per gunny bag or carton

Pressed Double Coupler Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10000 Kilograms Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Pressed Double Coupler

Exceptional Strength and Durability

Engineered from forged or pressed steel, the Pressed Double Coupler ensures high tensile strength and longevity, crucial for demanding construction environments. An anti-corrosive, electro-galvanized or hot dip galvanized finish protects against rust, making these couplers ideal for repeated use even in harsh outdoor conditions.

Certified Safety and Reliable Performance

Conforming to EN74 and BS1139 standards, these right angle couplers are thoroughly tested for performance and safety. Each unit secures two scaffold tubes at a perfect 90-degree angle, ensuring stable building support that construction professionals can trust on site.

Flexible Compatibility & Application

With the ability to fit standard 48.3 mm diameter scaffold pipes, these couplers offer versatile use in various scaffolding systems. Available in silver or golden yellow zinc plating, and packaged in sets of 25, they're user-friendly for both small and large-scale operations.

FAQ's of Pressed Double Coupler:

Q: How does the Pressed Double Coupler secure scaffold tubes in construction projects?

A: This coupler uses 1/2 inch BSW threaded bolts to firmly clamp two 48.3 mm OD scaffold pipes at a 90-degree right angle. Its pressed body and high-quality swivel bolts ensure tight, stable connections for structural support.Q: What standards does this coupler meet, and why are they important?

A: The Pressed Double Coupler is certified to EN74 and BS1139 standards, ensuring it meets international requirements for strength, safety, and load capacity-vital for safe scaffolding construction and building support.Q: When should I use a right angle (double) coupler instead of other scaffolding fittings?

A: You should use this right angle coupler when it's necessary to join two scaffold tubes at 90 degrees, which is essential for creating load-bearing scaffolding structures or frameworks requiring robust connections.Q: Where can this coupler be applied in construction projects?

A: It's suitable for all types of scaffolding applications, including temporary support, facade scaffolds, or general building maintenance, wherever strong, perpendicular tube connections are required.Q: What is the benefit of its anti-corrosive electro-galvanized or hot dip galvanized finish?

A: The advanced surface treatment provides long-lasting resistance to rust and environmental elements, extending the usable life of the coupler even with frequent re-use in outdoor or humid conditions.Q: How does its load capacity contribute to safety on site?

A: With a load-bearing strength of up to 6.25 kN, as tested under EN74 standards, this coupler reliably supports heavy scaffold loads, reducing the risk of structural failure and enhancing site safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Couplers and Fittings Category

Girder Coupler

Surface Finishing : Hotdip Galvanized / Zinc Plated

Material : Forged Steel / Malleable Iron

Other Features : Robust design, High strength, Corrosion resistance

Application : Used for connecting scaffold tubes to steel girders

Components : Two halves, Nut and Bolts

Thickness : 5 mm to 8 mm

Industrial Girder Coupler

Surface Finishing : Electrogalvanized / Hot Dip Galvanized

Material : Forged Steel

Other Features : Slip resistant, Reusable, Corrosion resistant

Application : Securing Scaffold Tubes to Structural Girders

Components : Coupler Body, Bolts, Nuts, Washers

Thickness : 5 mm

Industrial Joint Pin

Surface Finishing : Galvanized / Zinc Plated

Material : Mild Steel (MS)

Other Features : Easy to install, corrosionresistant

Application : Scaffolding, Construction Joints

Components : Joint Pin & Fasteners

Thickness : 3 mm 5 mm (approx)

Industrial Sleeve Coupler

Surface Finishing : Electro Galvanized

Material : Forged Steel

Other Features : Heavy Duty, Rust Resistant

Application : Scaffolding Joint, Pipe Joining

Components : Sleeve Coupler

Thickness : 58 mm

Send Inquiry

Send Inquiry