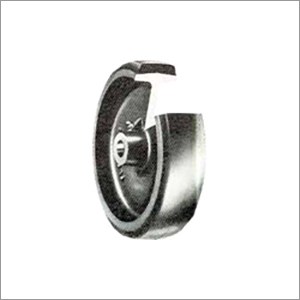

Rubber Bond

Rubber Bond Specification

- Product Type

- Rubber Bond

- Material

- Natural Rubber

- Type

- Bond

- Shape

- Round

- Technique

- Vulcanized

- Connection

- Bonding

- Surface Treatment

- Smooth

- Standard

- ASTM/DIN/ISO

- Thickness

- Customized

- Grade

- Industrial Grade

- Diameter

- Any available

- Length

- Any available

- Color

- Black

About Rubber Bond

Features:

-

Smooth & Reliable Performance

-

Accurate in Dimension

-

Industry Standard Sizes

-

Available in Different Designs

- No risk of losing any part

- Quick to mount and dismount

- Rust resistance

Versatile and Durable Applications

This Rubber Bond is particularly suited for industrial machinery, conveyor systems, and dampening tasks due to its superior temperature, chemical, and abrasion resistance. Its customizable size and thickness mean it can be precisely tailored to your specific operational requirements, ensuring optimal fit and performance in a wide range of industrial settings.

High Performance Engineering

Manufactured using advanced vulcanization techniques, this rubber bond delivers high tensile strength and excellent elongation, ensuring longevity even under tough operational stresses. Its smooth surface treatment allows for secure bonding and minimizes wear, contributing to reduced maintenance and downtime.

FAQ's of Rubber Bond:

Q: How is the Rubber Bond installed or connected in industrial applications?

A: The Rubber Bond is primarily installed using high bonding strength adhesives, ensuring a secure and lasting connection for machinery, conveyor systems, and dampening elements. Its smooth surface and vulcanized finish facilitate easy and reliable attachment.Q: What benefits does the Rubber Bond provide for industrial machinery and conveyor systems?

A: It offers outstanding oil, acid, and abrasion resistance, combined with low water absorption and high tensile strength. These features help extend equipment lifespan, reduce maintenance needs, and ensure reliable operation even under extreme temperatures or demanding conditions.Q: When is it recommended to use this Rubber Bond in an industrial environment?

A: This product is ideal for situations requiring high flexibility, significant load endurance, and resilience to harsh chemicals or mechanical wear. Use it when your systems or equipment need added protection or enhanced dampening in challenging temperature or chemical environments.Q: Where can the Rubber Bond be applied?

A: Suitable for a wide array of industrial settings, it can be utilized in conveyor systems, machinery pads, vibration dampers, and other equipment where its durable and high-bonding properties offer distinct operational advantages.Q: What customization options are available for this Rubber Bond?

A: Customization is available in terms of thickness, length, diameter, and shape. The product can be supplied as rolls or sheets in various grades, allowing you to match specific dimensional and performance requirements.Q: Describe the manufacturing process and material standards for this Rubber Bond.

A: The product is made from a high-quality blend of natural and other rubbers, processed via vulcanization for enhanced strength and elasticity. It adheres to ASTM, DIN, and ISO standards, ensuring consistent quality and performance.Q: How does the Rubber Bond handle exposure to harsh chemicals and temperature variations?

A: Thanks to its oil, acid, and abrasion resistance coupled with a temperature range of -40C to +100C, the Rubber Bond maintains its structural integrity and bond strength, even when exposed to aggressive industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Allied Equipments Category

Phenolic Fibre

Length : 13 Meter

Grade : Industrial Grade

Connection : Other, Solid

Thickness : 520 mm

Surface Treatment : Other, Smooth Finish

Material : Other , Phenolic Resin + Fibre

Industrial Trestle Scaffolding

Length : 2 m, 3 m, 4 m (customization available)

Grade : IS 1161 / IS 1239 Grade steel

Connection : Other, Bolt / Pin / Welding Type

Thickness : 2.5 mm / 3.0 mm

Surface Treatment : Other, Powder Coated / Painted / Hot Dip Galvanized

Material : Mild Steel

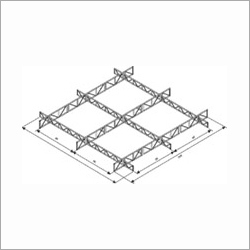

Ladder Beam-Truss

Length : Multiple Sizes (2m, 3m, 4m, 6m, 8m, 10m, or customized)

Grade : Q235 / Q345

Connection : Other, Welded & Bolted

Thickness : 3.0 mm

Surface Treatment : Other, Hot Dip Galvanized / PreGalvanized / Painted

Material : Other , High Tensile Steel

Industrial Single Ladder

Length : 6 to 20 Feet

Grade : Industrial Grade

Connection : Other, Welded

Thickness : 2.5 mm

Surface Treatment : Galvanized

Material : Aluminum

Send Inquiry

Send Inquiry