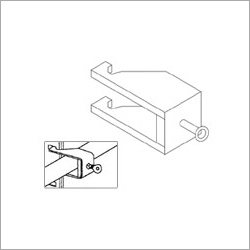

Wedge Sets

Wedge Sets Specification

- Color

- Silver, Yellow, or Customized

- Weight

- 0.25 kg to 1.5 kg

- Sleeve size

- Standard/Customized

- Technique

- Drop Forged

- Pin

- MS Pin or Customized

- Constitute

- Wedge and Tie Assembly

- Features

- Robust, Corrosion Resistant, Precise Fit

- Prop Head

- Compatible with standard props

- Product Type

- Scaffolding Wedge Set

- Material

- Mild Steel/Carbon Steel

- Components

- Wedge and tie rod set

- Diameter

- 16 mm to 20 mm

- Width

- 30 mm to 40 mm

- Length

- 100 mm to 200 mm

- Height

- 20 mm to 50 mm

- Thickness

- 3 mm to 10 mm

- Platform Loading Capacity

- High Load Bearing Capacity

- Surface Treatment

- Hot Dip Galvanized/Powder Coated

- Application

- Formwork, Scaffolding, and Construction

- Size

- Standard and Custom Sizes

About Wedge Sets

Universal Compatibility

Our wedge sets are engineered to fit most scaffolding systems used in formwork and construction across both indoor and outdoor settings. With diameters ranging from 16 mm to 20 mm and customizable sleeve sizes, they ensure a precise fit and reliable performance on site.

Automatic Self-Locking Mechanism

The wedge locking type features an automatic self-locking system, streamlining assembly and enhancing worker safety. This robust mechanism provides a secure hold, eliminates the need for manual adjustment, and supports high platform loading capacities.

Corrosion Resistant Durability

With surface treatments such as hot dip galvanizing or powder coating, our wedge sets boast exceptional resistance to rust and corrosion. This ensures long-lasting functionality, even in harsh weather conditions, maximizing the product's reusability over multiple construction cycles.

FAQ's of Wedge Sets:

Q: How do I use the wedge sets in scaffolding and formwork applications?

A: Simply assemble the wedge and tie rod set into your scaffolding or formwork system. The automatic self-locking mechanism engages instantly, securing components with minimal manual adjustment, ensuring stability and ease of use.Q: What are the benefits of the automatic self-locking wedge design?

A: The automatic self-locking design significantly enhances assembly speed and worker safety by preventing accidental loosening. It also offers consistent securement, thereby supporting high load-bearing performance across various construction scenarios.Q: Where can these wedge sets be used effectively?

A: These wedge sets are suitable for both indoor and outdoor construction sites, including applications in formwork, scaffolding, and structural support. Their robust material and corrosion resistance make them adaptable to any environmental condition.Q: What materials and surface treatments are available for these wedge sets?

A: We offer wedge sets manufactured from mild steel and carbon steel. Surface treatments include hot dip galvanizing for superior corrosion resistance, or powder coating in silver, yellow, or custom colors, ensuring a long operational lifespan.Q: Can these wedge sets be reused multiple times on different projects?

A: Yes, these sets are designed for multiple use. The high tensile strength, precision machining, and corrosion-resistant surface treatments ensure the components maintain their integrity through repeated cycles of installation and removal.Q: What is the standard packing type for shipment and storage?

A: Wedge sets are packed either in bags or steel drums, depending on quantity and customer requirements. Both options safeguard the components during transport and facilitate efficient storage on-site.Q: Are custom sizes and specifications available for specialized requirements?

A: Absolutely. In addition to standard sizes, we provide custom diameters, sleeve sizes, pin options, and surface treatments to suit specific needs and ensure a perfect fit for proprietary scaffolding systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Scaffolding Clamps Category

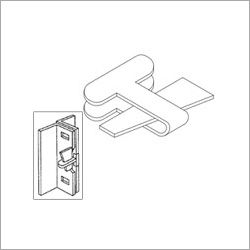

Timber Waling Clamp

Product Type : Timber Waling Clamp, Other

Surface Treatment : Galvanized for corrosion resistance, Other

Technique : Other, Forging and Machining

Material : Highgrade steel, Other

Application : Other, Used in construction to secure timber waling for formwork systems.

Constitute : other, Steel structure with bolt and nut assembly

Single Clamps -B - Clamps

Product Type : Single Clamps B Clamps, Other

Surface Treatment : Galvanized, Other

Technique : Forged

Material : Steel

Application : Scaffolding, Other

Constitute : other, Single Clamp

Industrial Timber Waling Clamp

Product Type : Other, Industrial Timber Waling Clamp

Surface Treatment : Other, Galvanized for corrosion resistance.

Technique : Other, Forging and machining.

Material : Other , Galvanized steel

Application : Other, Used for timber waling in construction and scaffolding projects.

Constitute : Metal components such as clamp body bolt and nuts., other

Industrial Rapid Clamps-Wedge Clamps-Column Clamps

Product Type : Industrial Rapid ClampsWedge ClampsColumn Clamps, Other

Surface Treatment : Other, Powdercoated

Technique : Other, Precision manufacturing

Material : Steel

Application : Industrial clamping for rapid fixing and column stabilization, Other

Constitute : Steel, other

Send Inquiry

Send Inquiry