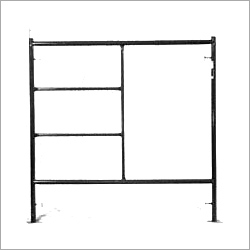

H-Frame Scaffolding

H-Frame Scaffolding Specification

- Constitute

- Mild Steel Tubes

- Technique

- Welded

- Color

- Blue, Customized

- Pin

- Joint Pin provided for frame connection

- Sleeve size

- Standard sleeve/joint

- Features

- High strength, Easy erection & dismantling, Durable, Stable

- Weight

- 23-26 kg/frame

- Product Type

- H-Frame Scaffolding

- Material

- Mild Steel

- Components

- Main Frame, Cross Braces, Joint Pins, Base Plate, Couplers

- Diameter

- 40 mm to 48.3 mm

- Width

- 1219 mm (4 ft)

- Length

- 2000 mm (2 m)

- Height

- 2000 mm (2 m)

- Thickness

- 2.6 mm to 3.0 mm

- Platform Loading Capacity

- Up to 200 kg/m (as per standard practice)

- Surface Treatment

- Painted / Hot Dip Galvanized / Powder Coated

- Application

- Building Construction, Maintenance, Industrial

- Size

- 1219 mm x 2000 mm

- Connection Type

- Pin & Lock or Bolt Connection

- Corrosion Resistance

- Yes

- Stackability

- Yes

- Frame Spacing

- 2 m (horizontal)

- Frame Shape

- H-Type Rectangular

- Usage

- Formwork Support, Masonry, Access Scaffold

- Scaffolding Height Adjustable

- Yes, as per project requirement

- Packaging

- Bundled or Loose

- Adjustable Base Plate

- Available

H-Frame Scaffolding Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10000 Kilograms Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About H-Frame Scaffolding

Superior Stability & Durability

Featuring a rectangular H-type structure with robust mild steel tubes and welded joints, this scaffolding system is designed for high strength and long-lasting performance. Its corrosion-resistant finishes-painted, powder-coated, or galvanized-further protect against harsh environmental conditions, ensuring stability and safety over extended use.

Easy Assembly & Adjustable Design

The pin & lock or bolt connection mechanism enables quick and secure assembly, while adjustable base plates and scaffolding height customization adapt to varied project demands. The bundled or loose packaging options, along with stackable components, simplify on-site handling, making this system ideal for dynamic job requirements.

Versatile Application

This H-Frame Scaffolding is engineered for a wide variety of uses, from supporting formwork and masonry tasks to creating reliable access scaffolds. Its platform supports up to 200 kg/m2, making it suitable for both lightweight and heavy-duty construction and industrial projects across India.

FAQ's of H-Frame Scaffolding:

Q: How is the H-Frame Scaffolding assembled and secured during installation?

A: The scaffolding system is assembled by connecting the main frames using joint pins, cross braces, and couplers. The pin & lock or bolt connection design ensures a quick and secure fit. Adjustable base plates provide additional stability and level the scaffold on uneven surfaces.Q: What types of projects is H-Frame Scaffolding suitable for?

A: This system is ideal for building construction, industrial maintenance, masonry work, and as an access scaffold. Its customizable height and platform loading capacity allow it to adapt to various project requirements, including formwork support and heavy-duty applications.Q: When should I use the adjustable features of this scaffolding?

A: Adjustable base plates and height options are best used when working on uneven terrain or when specific working elevations are required for the project. This flexibility ensures a safe and stable platform tailored to unique site conditions.Q: Where can the H-Frame Scaffolding be deployed?

A: With its corrosion-resistant surface treatment and strong construction, this scaffolding can be used in both indoor and outdoor settings across different climates in India. It is suitable for construction sites, factories, and maintenance areas.Q: What are the main benefits of using H-Frame Scaffolding?

A: This system offers high strength, durability, easy erection and dismantling, and excellent stability. Its stackable design and customizable features help increase efficiency, reduce setup time, and enhance workplace safety on a wide range of projects.Q: How does the surface treatment enhance the scaffolding's lifespan?

A: Options such as painting, hot-dip galvanization, or powder coating shield the mild steel framework from corrosion, extending the usable life of the scaffolding and minimizing maintenance needs in challenging environmental conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Frame System Category

Gravity Pins

Length : 150mm

Application : Scaffolding and construction support systems, Other

Product Type : Other, Construction accessories

Surface Treatment : Other, Electrogalvanized

Components : Gravity pins and locking mechanism, Other

Industrial Cross Brace

Length : Estimated length visible in image requires confirmation

Application : Support and stabilization in scaffolding structures, Other

Product Type : Other, Cross Brace

Surface Treatment : Other, Galvanized or painted (common)

Components : Two crossed bars forming a brace, Other

Height : Refer to specifications

Ladder Frame 5X5.1

Length : 5 ft

Application : Other, Construction Scaffolding

Product Type : Ladder Frame 5X5.1, Other

Surface Treatment : Powder Coated, Other

Components : Ladder Frame, Other

Height : 5 ft

Cross Brace

Length : Standard length of cross brace (e.g. 1.2m)

Application : Scaffolding system, Other

Product Type : Other, Cross Brace

Surface Treatment : Galvanized, Other

Components : Cross bracing rods, Other

Send Inquiry

Send Inquiry