Welcome to Our Company

Call Us :08045803837

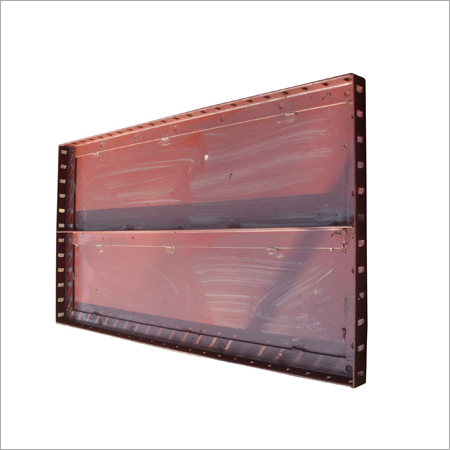

Shuttering Plate

Shuttering Plate Specification

- Technique

- Welded

- Pin

- Provision for pin at corners

- Weight

- Approx. 22-28 kg per plate

- Prop Head

- Compatible with standard prop heads

- Constitute

- Mild Steel Sheet & Angle

- Color

- Red

- Features

- Reusable, High Strength, Smooth Finish, Corrosion Resistant

- Product Type

- Mild Steel Shuttering Plate

- Material

- Mild Steel

- Components

- Main panel, side edges, stiffeners, corner angles

- Width

- 600 mm

- Length

- 1250 mm

- Height

- 50 mm

- Thickness

- 2.5 mm

- Platform Loading Capacity

- Up to 350 kg/m

- Surface Treatment

- Painted/Red oxide coated

- Application

- Concrete shuttering, slab support in construction

- Size

- 600 mm x 1250 mm

About Shuttering Plate

Holding great experience and expertise in this field, we are engaged in offering huge array of Shuttering Plate. Offered plate is manufactured by our highly skilled workforce in abidance with the set industry norms, using the top grade raw materials and the pioneering technology. This plate is widely utilized in construction industry for various casting applications. Before dispatching this equipment, it is made to pass assorted aspects of quality to avoid any kind of defect. Moreover, our valuable customers can avail this Shuttering Plate from us at market leading prices.

Features:

- Long service life with easy installation

- Light in weight and durable finish

- Corrosion and rust resistance

- Enhanced performance and less maintenance required

- User friendly design that makes it easy to use

Reusability and Durability

With reinforced, bent, and welded edges, these shuttering plates stand up to demanding construction cycles. The red oxide coated mild steel base ensures each plate resists corrosion and harsh site conditions, allowing for reuse up to 200 times with appropriate care and maintenance.

Heavy-Duty Strength for Versatile Projects

Engineered to bear loads up to 350 kg/m, these plates are suitable for both cuplock systems and various scaffolding configurations. Main panel, stiffeners, and corner angles work in unison to deliver a reliable platform for slab support and concrete works.

Optimized Design and Safety

Precision manufacturing achieves a smooth surface finish and flatness tolerance within 2 mm. The provision for corner pins and compatibility with standard prop heads enhances stability, making installation safer and more straightforward on construction sites.

FAQs of Shuttering Plate:

Q: How should Shuttering Plates with reinforced edges be maintained for maximum reusability?

A: To maximize reusabilityup to 200 cyclesclean plates after each use, inspect for damage, and reapply protective red oxide coating if needed. Store in a dry area to avoid corrosion.Q: What construction systems are compatible with these shuttering plates?

A: These plates are specifically designed to work seamlessly with cuplock and scaffolding systems. Their size and features also allow integration with standard prop heads on site.Q: When is the ideal application for these heavy-duty shuttering plates?

A: They are best suited for concrete shuttering and slab support, especially when heavy-duty load bearing (up to 350 kg/m) is required on construction projects.Q: Where can the plates be used within a construction project?

A: These shuttering plates are typically deployed as a base for casting concrete slabs on floors or elevated areas, offering both support and a flat surface for formwork.Q: What is the process for installing the plates on site?

A: Align the plates as per project requirements, use the pin provisions at corners for interlocking, and ensure compatibility with prop heads and cuplock systems for a stable structure.Q: What materials constitute the shuttering plates and how do they contribute to strength?

A: Made from mild steel sheets and angles, the combination delivers high strength, smooth finish, and long-term resilience due to welded, reinforced edges.Q: What are the core benefits of choosing these shuttering plates?

A: Key advantages include high reusability, corrosion resistance, heavy-duty load accommodation, smooth finish for concrete work, and compatibility with most scaffolding systems.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free