Industrial Joint Pin

Industrial Joint Pin Specification

- Shape

- Round / Cylindrical

- Load Capacity

- High load bearing (up to 1 ton, varies by size)

- Application

- Scaffolding, Construction Joints

- Hole Size

- 10 mm 16 mm (custom as required)

- Other Features

- Easy to install, corrosion-resistant

- Components

- Joint Pin & Fasteners

- Thickness

- 3 mm 5 mm (approx)

- Material

- Mild Steel (MS)

- Surface Finishing

- Galvanized / Zinc Plated

- Tensile Strength

- High tensile strength suitable for construction use

- Usage

- Reusable, Suitable for heavy-duty applications

- Connection Type

- Slip-on / Coupling

- Length

- 200 mm 300 mm (standard)

- Standards

- IS Standard Compliant

- Diameter

- 38 mm 60 mm

- Color

- Silver / Metallic

About Industrial Joint Pin

Features:

-

Smooth & Reliable Performance

-

Accurate in Dimension

-

Industry Standard Sizes

-

Available in Different Designs

- No risk of losing any part

- Quick to mount and dismount

- Rust resistance

Superior Construction and Materials

Made from high-quality mild steel, the Industrial Joint Pin exhibits excellent durability and stability. Its galvanized or zinc-plated surface provides added corrosion resistance, making it suitable for outdoor and demanding industrial environments. This combination of strength and surface protection offers long-term reliability, even in challenging conditions.

Versatile Application and Easy Installation

Thanks to its slip-on and coupling connection types, the joint pin is easily installable without specialized tools or extensive labor. Suited for both scaffolding and construction joints, it adapts to diverse building needs. Its round or cylindrical shape and customizable hole sizes further ensure a precise fit for various structural setups.

Comprehensive Standards Compliance

Our Industrial Joint Pin is IS standard compliant, ensuring safety and quality for use across India. This adherence to recognized industry norms instills confidence in contractors and engineers, guaranteeing optimum performance and compatibility with other standardized components.

FAQ's of Industrial Joint Pin:

Q: How is the Industrial Joint Pin installed in construction projects?

A: The Industrial Joint Pin utilizes a slip-on or coupling connection, allowing for quick and straightforward installation. Simply align the pin with the joint, slide or couple it into position, and secure it with appropriate fasteners to ensure stability.Q: What materials and surface finish are used for manufacturing these joint pins?

A: These joint pins are manufactured from mild steel and feature a galvanized or zinc-plated finish, providing excellent durability and corrosion resistance suitable for heavy-duty usage.Q: When should I opt for an Industrial Joint Pin for construction work?

A: Choose the Industrial Joint Pin when requiring reusable connectors with high tensile strength and load-bearing capacity. They are especially beneficial for scaffolding, temporary connections, and heavy-duty construction joints in compliance with IS standards.Q: Where are these joint pins commonly applied?

A: Industrial Joint Pins are mainly used in scaffolding systems and construction joints. Their versatility allows for application across various site conditions, especially in projects needing secure and stable connections.Q: What is the standard size range and are customizations available?

A: Standard lengths range from 200 mm to 300 mm, with diameters between 38 mm and 60 mm. Customizations such as hole size (10 mm-16 mm) and thickness (3 mm-5 mm) are also available to suit specific requirements.Q: How does the joint pin benefit construction professionals?

A: The Industrial Joint Pin offers high load-bearing capacity (up to 1 ton, subject to size), is reusable, and ensures secure connections with minimal installation effort. Its corrosion-resistant finish and compliance with IS standards provide long-term value and peace of mind for builders.Q: What process is followed to ensure product quality and standards compliance?

A: Each joint pin undergoes rigorous quality checks and is manufactured to align with IS standards. The process includes precise material selection, surface finishing, and dimensional verification to ensure reliability and safety in all usages.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Couplers and Fittings Category

Industrial Light Duty Double Coupler and Light duty Swivel Coupler

Surface Finishing : Electro Galvanized/Hot Dip Galvanized

Shape : Rectangular Clamp with Bolted Connection

Load Capacity : Up to 6 kN (Light Duty)

Material : Mild Steel

Other Features : Corrosion Resistant, Precision Forged, Reusable

Components : Double Coupler, Swivel Coupler

Industrial Putlog Coupler

Surface Finishing : Electro Galvanized / Hot Dip Galvanized

Shape : Rectangular Clamp with Curved Jaw

Load Capacity : 1.5 kN 2.0 kN

Material : Forged Steel or Pressed Steel

Other Features : Rust Resistant, Reusable

Components : Putlog Coupler Body, Bolts, Nuts, Washer

Industrial Fencing Coupler

Surface Finishing : Hotdip galvanized

Shape : Rectangular

Load Capacity : Up to 1,200 kg

Material : Galvanized steel

Other Features : Corrosion resistant

Components : Coupler body, securing bolts, nuts

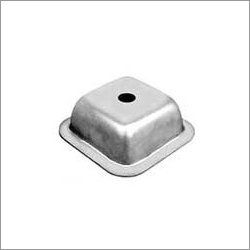

Industrial Pallet Bowl

Surface Finishing : Galvanized

Shape : Round

Load Capacity : Up to 2000 kg

Material : Mild Steel

Other Features : Corrosion resistant, Heavy Duty Construction

Components : Industrial Pallet Bowl

Send Inquiry

Send Inquiry