Natural Phenolic Fibre

Natural Phenolic Fibre Specification

- Product Type

- Natural Phenolic Fibre

- Material

- Phenolic Resin Impregnated Paper / Fibre

- Type

- Phenolic Fibre Sheet

- Shape

- Sheet, Rod, Tube

- Technique

- Hot Pressed Laminated

- Connection

- Mechanical Fastening

- Surface Treatment

- Smooth, Matte Finish

- Standard

- IS 2036 / IEC Standards

- Thickness

- 0.5 mm to 50 mm

- Grade

- Industrial

- Diameter

- Standard / Custom

- Length

- Customizable

- Color

- Natural Brown

About Natural Phenolic Fibre

Features:

-

Smooth & Reliable Performance

-

Accurate in Dimension

-

Industry Standard Sizes

-

Available in Different Designs

- No risk of losing any part

- Quick to mount and dismount

- Rust resistance

Superior Mechanical and Electrical Performance

Natural Phenolic Fibre stands out for its robustness, combining high compressive and tensile strengths with excellent electrical insulation. Its natural brown appearance, glossy or matte finish, and precision-cut edges cater to diverse industrial design needs, while the smooth, matte surface ensures uniformity across applications.

Tailored for Rigorous Industrial Applications

This product is engineered for demanding environments, offering high flame retardancy, excellent machinability, and resistance to water and moisture. Its adaptability in terms of thickness, length, and shape makes it an ideal solution for custom applications in electrical, structural, and mechanical sectors.

Compliance and Quality Assurance

Meeting IS 2036 and IEC standards, and being RoHS compliant, Phenolic Fibre assures safety, environmental responsibility, and consistent quality. Manufactured using advanced hot pressed laminated techniques, it ensures long-term performance and reliability in various operating conditions.

FAQ's of Natural Phenolic Fibre:

Q: How is Natural Phenolic Fibre commonly used in industrial applications?

A: Natural Phenolic Fibre is extensively utilized in the production of electrical insulation components, structural supports, and mechanical parts due to its excellent mechanical strength, thermal stability, and electrical insulation properties. It is ideal for use where flame retardancy and moisture resistance are required.Q: What benefits does Phenolic Fibre offer over conventional materials?

A: Phenolic Fibre provides high compressive and tensile strengths, superior moisture and flame resistance, and self-extinguishing characteristics. It is lightweight, offers enhanced machinability, and is available in various finishes and sizes, making it highly adaptable for industrial use.Q: When should I select this material for my project?

A: It is best to choose Natural Phenolic Fibre when your application mandates robust electrical insulation, flame retardancy, and consistent mechanical performance within the operating temperature range of -20C to 120C. It is particularly useful in heavy-duty and safety-critical environments.Q: Where can the Phenolic Fibre sheets, rods, or tubes be installed?

A: These products can be installed in electrical assemblies, control panels, mechanical frameworks, and structural partitions across industrial plants, machinery, and equipment. They are suited for both indoor and sheltered outdoor locations, where environmental stability is important.Q: What is the manufacturing process for Phenolic Fibre products?

A: Phenolic Fibre products are made through a hot pressed laminated process, where phenolic resin impregnated paper or fibre is cyclically compressed and heated, resulting in a dense, uniform material with superior mechanical and electrical properties.Q: How does the product perform in moist or humid environments?

A: Thanks to its high moisture resistance and low water absorption rate ( 5% after 24 hours at 23C), Natural Phenolic Fibre retains its structural integrity and insulation properties even in humid conditions, making it suitable for demanding environments.Q: What customization options are available for Phenolic Fibre products?

A: You can order Phenolic Fibre in various thicknesses (0.5 mm to 50 mm), customizable lengths, and diameters. Finishes include glossy or matte, with precision or straight-cut edges, and it is available in the form of sheets, rods, or tubes, tailored to your specific industrial needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Allied Equipments Category

Trestle Scaffolding

Connection : Other, Fixed with Bolted Joints

Surface Treatment : Other, Painted/Galvanized

Material : Mild Steel

Length : 2 m / 2.5 m / 3 m

Shape : Other, Rectangular Frame

Grade : Mild Steel, IS 1161/1239

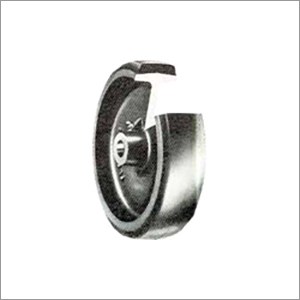

Phenolic Fibre

Connection : Other, Solid

Surface Treatment : Other, Smooth Finish

Material : Other , Phenolic Resin + Fibre

Length : 13 Meter

Shape : Round

Grade : Industrial Grade

Industrial Post Pallets

Connection : Other, Welded

Surface Treatment : Other, Powder Coated

Material : Mild Steel

Length : 1200 mm

Shape : Other, Rectangular Base with Round Posts

Grade : Industrial Grade

Rubber Bond

Connection : Other, Bonding

Surface Treatment : Other, Smooth

Material : Other , Natural Rubber

Length : Any available

Shape : Round

Grade : Industrial Grade

Send Inquiry

Send Inquiry