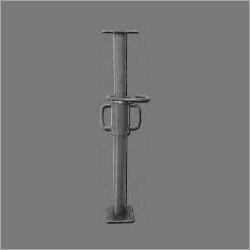

Push & Pull Props

Push & Pull Props Specification

- Constitute

- MS (Mild Steel)

- Pin

- Steel Pin

- Weight

- 15 kg - 25 kg

- Technique

- Hot Rolled

- Color

- Blue, Red, Painted or Customized

- Prop Head

- U Head / Flat Head

- Sleeve size

- Standard / Customized

- Features

- Heavy Duty, Corrosion Resistance, Easy To Install, Adjustable

- Product Type

- Push & Pull Prop

- Material

- Mild Steel

- Components

- Outer Tube, Inner Tube, Nut, Base Plate, Jack, Pin, Collar Nut

- Diameter

- 48-60 mm

- Width

- Varies (standard widths per client requirements)

- Length

- Adjustable 1.5m - 5.5m

- Height

- Adjustable as per site requirement

- Thickness

- 2.0 mm to 4.0 mm

- Platform Loading Capacity

- 1-3 Tons

- Surface Treatment

- Paint Coated / Galvanized

- Application

- Construction, Slab Support, Scaffolding

- Size

- Customized as per requirement

About Push & Pull Props

Features:

-

Smooth & Reliable Performance

-

Accurate in Dimension

-

Industry Standard Sizes

-

Available in Different Designs

- No risk of losing any part

- Quick to mount and dismount

- Rust resistance

Exceptional Capacity and Adaptability

Engineered to handle platform loads from 1 to 3 tons and support site requirements with adjustable height and length, these push & pull props meet varied construction challenges. Their robust design ensures reliability and safety in both temporary and long-term projects.

Premium Build for Longevity

Constructed from high-grade mild steel using hot-rolled techniques, these props resist corrosion and environmental wear. The base plate and components are finished with either paint or galvanization for enhanced durability, making them ideal for demanding conditions.

User-Friendly Installation and Operation

With features like adjustable sleeves and threaded/socketed connections, these props are designed for quick assembly and easy adjustment on site. Their ergonomic build minimizes installation time and effort, helping workers achieve precise positioning wherever needed.

FAQs of Push & Pull Props:

Q: How do I install Push & Pull Props with a base plate?

A: Installation is straightforward: position the prop at the required location, adjust the length using the collar nut, and secure with the steel pin. The base plate provides stability, and the threaded or socketed end ensures a firm connection to the supported structure.Q: What are the recommended applications for these props?

A: These props are mainly used for construction, including slab support, scaffolding, and stabilization of formwork. Their versatility allows for use in both vertical and horizontal orientations, adapting to various site requirements.Q: When should I choose cast iron versus steel nut types?

A: Cast iron nuts offer robust resistance to compression, ideal for static loads, while steel nuts provide greater durability for dynamic or repetitive applications. Selection depends on project demands and expected load variations.Q: Where can these props be used effectively?

A: Push & Pull Props are suitable for indoor and outdoor construction sites, including buildings, bridges, and industrial structures. Their corrosion-resistant finishes enable reliable performance across diverse environments in India and abroad.Q: What is the process for adjusting the length and height?

A: Simply loosen the collar nut to slide the inner tube to the desired length, then tighten the nut and insert the steel pin to lock the position. Both height and width can be customized according to specific client requirements prior to delivery.Q: How does the surface treatment benefit the props?

A: Painted or galvanized surface treatments protect the prop from rust and environmental degradation, extending service life and reducing maintenance needs over time.Q: What makes these props advantageous compared to traditional supports?

A: Their heavy-duty construction, adjustable dimensions, corrosion resistance, and low maintenance requirements make them safer and more cost-effective, while their customizable features ensure a perfect fit for each project.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Props & Shoring Category

Industrial Light Weight Prop

Platform Loading Capacity : 1.53 tons

Length : Variable length based on adjustment range

Components : Other, Inner tube outer tube base plate top plate adjustable collar

Prop Head : Other, Flat plate or Uhead option for prop contact

Diameter : 3860mm

Sleeve size : Standard sleeve size

Light Weight Prop

Platform Loading Capacity : 1.5 tons

Length : Customizable based on project requirements

Components : Prop Body Nut Sleeve and Base Plate, Other

Prop Head : Other, Flat head with holes for formwork support

Diameter : Outer Tube: 60mm Inner Tube: 48mm

Sleeve size : 60mm diameter

Industrial Push & Pull Props

Platform Loading Capacity : Suitable for heavyduty applications (specific capacity unknown)

Length : Variable Length (specific measurement unknown)

Components : Other, Prop cylinder head plate base plate adjustment mechanism

Prop Head : Other, Flat plate with mounting holes

Diameter : Adjustable Diameter (specific measurement unknown)

Sleeve size : Adjustable sleeve size (specific measurement unknown)

Send Inquiry

Send Inquiry