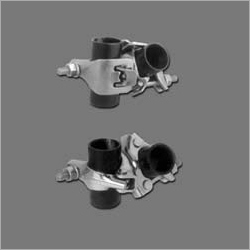

Industrial Drop Forged Double Coupler

Industrial Drop Forged Double Coupler Specification

- Shape

- Rectangular with dual clamp design

- Load Capacity

- Up to 6 kN

- Application

- Scaffolding and Construction

- Other Features

- High corrosion resistance, heavy-duty, reusable

- Components

- Base plate, bolts, nuts, washer, forged clamps

- Hole Size

- Suitable for 48.3 mm OD Pipe

- Thickness

- 4 mm to 6 mm

- Material

- Carbon Steel or Mild Steel

- Surface Finishing

- Electro-galvanized or Hot Dip Galvanized

- Minimum Order Quantity

- 100 Pieces

- Lifespan

- Long life with proper maintenance

- Tolerance

- ±0.5 mm

- Weight

- Approx. 1.05 kg per piece

- Temperature Resistance

- -20°C to +50°C

- Packaging Type

- Gunny bags or custom packaging

- Bolt Size

- 16 mm hex head

- Connection Type

- Right angle (90 degree) coupling

- Clamping Range

- 42.4 mm to 49 mm OD Pipes

About Industrial Drop Forged Double Coupler

Features:

-

Smooth & Reliable Performance

-

Accurate in Dimension

-

Industry Standard Sizes

-

Available in Different Designs

- No risk of losing any part

- Quick to mount and dismount

- Rust resistance

Heavy-duty Performance for Construction

Built for demanding job sites, this double coupler provides a secure and stable solution for joining scaffolding pipes at right angles. Its robust construction using carbon or mild steel guarantees high load capacity, making it ideal for both temporary and permanent structures.

Precision Engineering and Compatibility

Every coupler is manufactured to tight tolerances (0.5 mm), ensuring a reliable fit on pipes with outer diameters from 42.4 mm to 49 mm. The hole size matches the standard 48.3 mm OD, and the dual clamp design provides excellent stability during application.

Enhanced Durability and Corrosion Resistance

With optional electro-galvanized or hot dip galvanized surface finishing, these couplers resist corrosion even in tough environmental conditions. Their extensive temperature resistance-from -20C up to +50C-assures longevity with proper maintenance on site.

FAQ's of Industrial Drop Forged Double Coupler:

Q: How is the Industrial Drop Forged Double Coupler typically used on construction sites?

A: The double coupler securely connects two pipes at a right angle, providing strong joints for scaffolding arrangements in construction and industrial projects. Its dual clamp design ensures the pipes remain stable and aligned, supporting heavy loads during various operations.Q: What is the process for installing this coupler on scaffolding pipes?

A: Installation involves positioning the coupler at the intersection of two pipes, tightening the 16 mm hex head bolts using standard tools, and ensuring both clamps are firmly secured. The tolerance of 0.5 mm allows for a precise, snug fit that enhances safety and structural rigidity.Q: When should the coupler undergo maintenance, and what does it involve?

A: To achieve long service life, couplers should be inspected regularly for signs of wear, corrosion, or bolt loosening. Maintenance typically includes cleaning, checking for damage, and reapplying protective coatings if necessary, particularly after exposure to harsh environments.Q: Where is this drop forged double coupler manufactured and exported from?

A: These couplers are manufactured, supplied, and exported from India, where they are produced under strict quality control standards to ensure consistent performance, durability, and compatibility with international scaffolding requirements.Q: What are the benefits of using electro-galvanized or hot dip galvanized surface finishes?

A: Both finishing options offer robust protection against rust and corrosion. Electro-galvanization provides a smooth, even coat, while hot dip galvanization offers a thicker, more resilient layer-making the coupler highly suitable for outdoor or humid environments.Q: Can the coupler accommodate different pipe thicknesses and diameters?

A: Yes, the coupler is designed with adjustable clamps and a tolerance of 0.5 mm, allowing it to fit pipes with outer diameters from 42.4 mm to 49 mm and thicknesses between 4 mm and 6 mm, ensuring versatility across a range of scaffolding systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Couplers and Fittings Category

Pressed Double Coupler

Material : Forged or Pressed Steel

Other Features : Anticorrosive, Reusable, Conforms to BS1139/EN74 standards

Surface Finishing : Electrogalvanized / Hot Dip Galvanized

Hole Size : Designed for 48.3 mm diameter scaffolding tube

Shape : Double Coupler (Right Angle) Clamp

Load Capacity : Up to 6.25 kN (as per EN 74 Standard)

Light Duty Double Coupler and Light duty Swivel Coupler

Material : Pressed Steel

Other Features : Drop forged fasteners, corrosion resistant, suitable for light duty applications

Surface Finishing : Electrogalvanized / Hot Dip Galvanized

Hole Size : 48.3 mm (suitable for standard scaffolding tubes)

Shape : Rectangular base with clamp design

Load Capacity : Approx. 0.751.0 kN

Industrial Putlog Head Adopter

Material : Mild Steel

Other Features : Corrosion Resistant, Strong Build, Easy Fitting

Surface Finishing : Hot Dip Galvanized / Painted

Hole Size : Standard 13 mm 16 mm

Shape : Rectangular with Flanged Ends

Load Capacity : Upto 250 kg (dependent on application)

Drop Forged Putlog Coupler

Material : Drop Forged Steel

Other Features : Designed for ease of installation and removal; provides secure, nonslip grip on scaffolding tubes

Surface Finishing : Electro Galvanized or Hot Dip Galvanized

Hole Size : Accommodates standard scaffolding pipes of 48.3 mm OD

Shape : Rectangular Coupler Body with Fitted Bolt

Load Capacity : Safe working load up to 6.25 kN

Send Inquiry

Send Inquiry