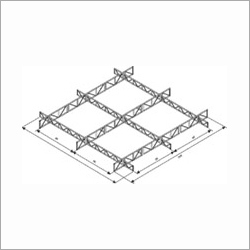

Ladder Beam-Truss

Ladder Beam-Truss Specification

- Product Type

- Scaffolding Truss

- Material

- High Tensile Steel

- Type

- Ladder Beam Truss

- Shape

- Round Pipe

- Technique

- Welded

- Connection

- Welded & Bolted

- Surface Treatment

- Hot Dip Galvanized / Pre-Galvanized / Painted

- Standard

- EN39 / EN74 / BS1139

- Thickness

- 3.0 mm

- Grade

- Q235 / Q345

- Diameter

- 48.3 mm

- Length

- Multiple Sizes (2m, 3m, 4m, 6m, 8m, 10m, or customized)

- Color

- Silver / Metallic Grey

- Application

- Building Construction, Industrial, Infrastructure Projects

- Rung Pipe

- 48.3 mm OD x 3.0 mm Thick

- Width

- 300 mm (approximate centre to centre of pipes)

- Main Tube

- 48.3 mm OD x 3.0 mm Thick

- Usage

- Used for spanning scaffolding structures and supporting heavy loads

- Load Capacity

- High Load Bearing Capacity for Construction & Industrial Applications

- End Fittings

- Fitted with Casted End or Standard Coupler

- Horizontal Pipe Spacing

- Approx. 305 mm

- Corrosion Resistance

- Excellent due to Hot Dip Galvanization

- MOQ

- Negotiable / Customizable

- Feature

- Lightweight, High Strength, Easy to Assemble, Durable

- Package

- Packed in Steel Bundles or as per requirement

About Ladder Beam-Truss

High Strength, Durable Construction

Manufactured from high tensile steel grades Q235 or Q345, Ladder Beam-Trusses provide unmatched strength and durability. Their welded and bolted design enhances structural stability, making them reliable for demanding construction environments. The galvanized surface ensures longevity, even in harsh outdoor conditions.

Flexible Sizing for Diverse Applications

Available in multiple lengths and with customizable features, Ladder Beam-Trusses cater to various project requirements. The round pipe structure and standard dimensions guarantee compatibility with global scaffolding standards, making them suitable for building, industrial, and infrastructure projects.

Superior Corrosion Resistance

Each beam undergoes hot dip galvanization, protecting against rust and weathering. This advanced surface treatment ensures excellent performance in outdoor installations and reduces maintenance costs over the lifespan of the truss.

FAQ's of Ladder Beam-Truss:

Q: How is the Ladder Beam-Truss installed in scaffolding systems?

A: The Ladder Beam-Truss is designed for straightforward assembly using either casted end fittings or standard couplers. Its welded and bolted connections ensure rapid and secure integration into scaffolding structures, supported by its compatibility with common standards like EN39, EN74, and BS1139.Q: What makes the Ladder Beam-Truss suitable for heavy load applications?

A: Constructed from high tensile steel (Q235/Q345) with 48.3 mm OD and 3.0 mm thick pipes, the truss handles substantial loads without compromising structural integrity. The hot dip galvanization further enhances its resistance to stress and corrosion under demanding conditions.Q: Where can Ladder Beam-Trusses be used effectively?

A: These trusses are ideal for building construction, industrial sites, and infrastructure projects, especially where high load-bearing capacity and long spans are required. They support heavy equipment and provide safe access within scaffolding structures.Q: What are the available sizes and customization options for Ladder Beam-Trusses?

A: Lengths range from 2m to 10m, with options for custom dimensions according to project needs. Rung and main tube sizes follow 48.3 mm OD, complying with industry standards. Packing, color, and quantity can also be tailored to client requirements.Q: How does hot dip galvanization benefit the Ladder Beam-Truss?

A: The hot dip galvanization process provides an excellent protective coating, making the Ladder Beam-Truss highly resistant to corrosion and weathering. This ensures longer product lifespan and reliable performance in outdoor and industrial environments.Q: What is the process for ordering Ladder Beam-Trusses from suppliers in India?

A: Orders can be customized according to project specifications, including size, surface treatment, packaging, and end fitting preferences. Manufacturers and exporters in India offer negotiable minimum order quantities and efficient delivery schedules to meet global demands.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Allied Equipments Category

Natural Phenolic Fibre

Product Type : Other, Natural Phenolic Fibre

Length : Customizable

Standard : IS 2036 / IEC Standards

Technique : Other, Hot Pressed Laminated

Connection : Other, Mechanical Fastening

Material : Other , Phenolic Resin Impregnated Paper / Fibre

Industrial Rubber Bond

Product Type : Other, Industrial Rubber Bond

Length : 15 Meter

Standard : IS Standard

Technique : Other, Hot Pressed Bonding

Connection : Other, Bonded

Material : Other , High Quality Rubber

Industrial Trestle Scaffolding

Product Type : Other, Industrial Trestle Scaffolding

Length : 2 m, 3 m, 4 m (customization available)

Standard : IS 3696 / BS EN 12811

Technique : Other, Cold Rolled / Hot Rolled

Connection : Other, Bolt / Pin / Welding Type

Material : Mild Steel

Industrial Shed Cloths

Product Type : Other, Industrial Shed Cloths

Length : 50 Meter

Standard : IS 14611:1998

Technique : Other, Woven

Connection : Other, Stitched Edges

Material : HDPE

Send Inquiry

Send Inquiry